What is the Death Wobble? The “Death Wobble” is a violent, uncontrollable shaking or oscillation of the front end of a Jeep, often occurring after hitting a bump or pothole. Can I fix it myself? Yes, many common causes of the Death Wobble can be diagnosed and repaired by a DIYer with basic mechanical skills and tools. Who is most affected? Jeeps, particularly those with lifted suspensions, larger tires, or modifications to the steering and suspension components, are most prone to experiencing the Death Wobble.

The Death Wobble is a terrifying phenomenon that can strike suddenly and without warning. One moment you’re cruising down the road, and the next, your Jeep is bucking and shaking so violently that it feels like the wheels are about to fly off. It’s a heart-stopping experience that can leave even the most seasoned off-roader rattled. But fear not, fellow Jeep enthusiasts! This guide will break down exactly what causes this dreaded wobble and, more importantly, how to fix it.

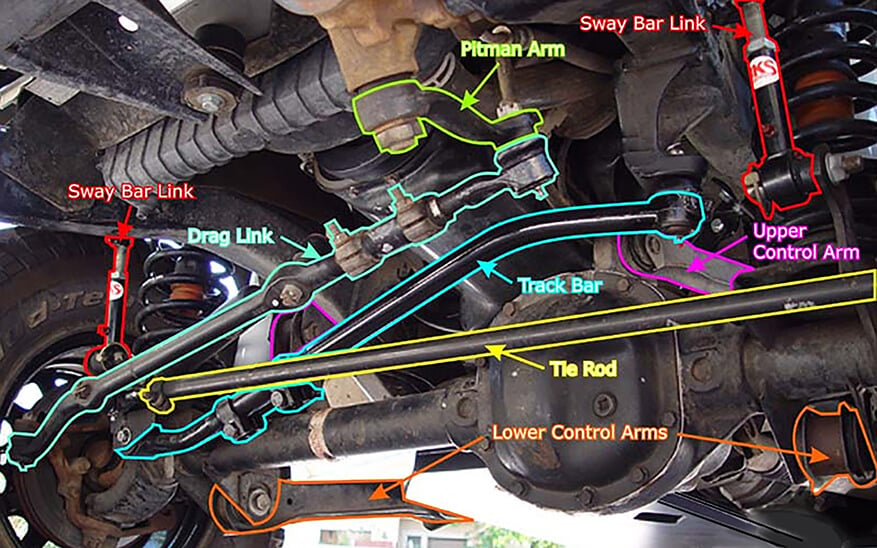

Image Source: www.quadratec.com

Deciphering the Wobble: What Triggers It?

The Death Wobble isn’t caused by a single faulty part. Instead, it’s a chain reaction. One worn or loose component creates a slight movement. When that movement hits a bump or stress point, it gets amplified. This amplified movement then stresses another component, causing it to move, and so on. It’s like a domino effect for your Jeep’s front end.

Several key areas in your Jeep’s steering and suspension are common culprits. We’ll dive deep into each of them.

The Steering System’s Role

Your Jeep’s steering system is responsible for translating your input at the steering wheel into directional changes for the front wheels. When parts of this system are worn or misaligned, they can easily get into a self-perpetuating oscillation.

-

Jeep Steering Stabilizer: This is often the first thing people think of when they hear “Death Wobble.” While a worn or improperly installed steering stabilizer can contribute to or mask the wobble, it’s rarely the root cause. Think of it as a band-aid. It can temporarily dampen the shaking, but if the underlying problem isn’t fixed, the wobble will return. A healthy steering stabilizer is crucial for smooth steering, but it’s not the only player in town.

-

Jeep Tie Rod and Drag Link: These are critical components that connect your steering system to your wheels. The tie rod connects the steering knuckle on one side to the steering box or steering rack. The drag link connects the opposite steering knuckle to the pitman arm of the steering box.

- Tie Rod Ends: These are ball joints that allow for movement. If the grease inside them dries out, or if the seals crack, dirt and water can get in, causing wear and play. Loose tie rod ends allow the wheels to move independently in a way that can trigger the wobble.

- Drag Link: Similar to the tie rod, the drag link can develop wear in its joints. A worn drag link can allow for excessive play in the steering, contributing to the Death Wobble.

Suspension Components: The Foundation of Stability

The suspension system absorbs shocks from the road and keeps your tires in contact with the ground. Any looseness or wear in these parts can lead to instability.

-

Jeep Ball Joint Replacement: Ball joints are pivot points that connect the control arms to the steering knuckles. They allow the wheels to turn and the suspension to move up and down. Worn ball joints develop play, meaning there’s too much looseness. This play can allow the wheel to shift slightly when hitting a bump, initiating the wobble. If your ball joints are worn, they need replacing.

-

Jeep Caster Adjustment: Caster is the angle of the steering axis when viewed from the side. Proper caster helps the wheels want to self-center. Too little caster can make steering feel light and contribute to wobble. In lifted Jeeps, caster can be negatively affected by the change in suspension geometry. Adjusting caster can sometimes help, but if the underlying cause is worn parts, adjustment alone won’t solve it.

-

Jeep Control Arm Bushings: Control arms connect the Jeep’s frame to the axles. They have rubber or polyurethane bushings at each end to absorb vibrations and allow for suspension movement. When these bushings wear out, they become soft, cracked, or loose. This allows the control arms to move around excessively, affecting wheel alignment and contributing to instability and wobble.

-

Jeep Track Bar Repair: The track bar (also known as a panhard rod) is a crucial component that prevents the front axle from shifting side-to-side under the Jeep’s body. It’s mounted at an angle. If the track bar itself is bent, or if the bushings or bolts at either end are worn or loose, the axle can move laterally. This lateral movement is a very common trigger for the Death Wobble. A damaged track bar or worn mounting points will need repair or replacement.

Wheel and Tire Issues

Even your tires and wheels can play a role in this unsettling phenomenon.

-

Jeep Tire Balance: Improperly balanced tires can cause vibrations, especially at certain speeds. While typically not the primary cause of the Death Wobble, unbalanced tires can exacerbate existing looseness in the steering and suspension, making the wobble worse.

-

Jeep Wheel Bearing Replacement: Wheel bearings allow your wheels to spin freely. If a wheel bearing is worn out, it creates excessive play in the wheel assembly. This play can allow the wheel to wobble on its hub, feeding directly into the Death Wobble cycle.

Other Potential Contributors

- Loose Steering Box: The steering box translates the rotation of the steering column into the movement of the tie rods. If the bolts holding the steering box to the frame are loose, or if the internal gears within the box are worn, it can introduce play into the system, leading to wobble.

- Worn U-Joints: While less common as a direct cause, severely worn universal joints in the front driveshaft can sometimes introduce vibrations that might mimic or worsen a Death Wobble.

Diagnosing the Wobble: Pinpointing the Problem

Before you start replacing parts, you need to figure out what’s causing the wobble. This requires a systematic approach.

The Bounce Test (for Shocks)

While worn shocks can contribute to bouncing, they are rarely the sole cause of the Death Wobble itself. However, it’s a quick check: push down hard on each corner of your Jeep. A properly functioning shock absorber will absorb the bounce and stop the motion quickly. If the Jeep continues to bounce excessively, your shocks may need replacing, but this is usually a secondary issue for the Death Wobble.

Visual Inspection: Getting Your Hands Dirty

This is the most important part of diagnosis. You’ll need to get under your Jeep and inspect all the steering and suspension components.

Tools you’ll need:

- Jack and jack stands (essential for safety!)

- Wheel chocks

- Gloves

- Flashlight

- Pry bar or large screwdriver

- Wrench set and socket set

- Torque wrench (for reassembly)

Inspection Steps:

- Safety First: Park your Jeep on a level surface. Engage the parking brake and block the rear wheels with chocks.

- Lift and Support: Safely lift the front end of your Jeep using a jack and place it securely on jack stands. Ensure the stands are placed on solid frame points, not suspension components. The front wheels should be hanging freely.

- Check Tire Pressure: Ensure all tires are inflated to the correct pressure. Uneven pressure can cause handling issues.

- Inspect Tires: Look for uneven wear patterns, such as feathering or cupping, which can indicate alignment problems or worn suspension parts. Check for any damage to the tire sidewalls.

-

Shake Test – The Core of Diagnosis: This is where you’ll find the play. With the wheels hanging, have a helper gently rock the steering wheel back and forth (left and right) while you observe and feel the components.

- Steering Wheel Play: Grab the steering wheel. If you can turn it several inches before the wheels start to move, you have excessive play, likely in the steering box or tie rod ends.

- Tie Rod Ends: Grab the tie rod firmly and try to move it up and down and side to side. Any noticeable play or looseness indicates worn tie rod ends.

- Drag Link: Grab the drag link (the link connecting the pitman arm to the steering knuckle) and try to move it up and down. Again, any looseness means it’s likely worn.

- Ball Joints: This is crucial. Try to wiggle the tire by hand, pushing and pulling on the top and bottom. If the wheel moves in its assembly, you likely have worn ball joints. You can also use a pry bar inserted between the ball joint and the steering knuckle to check for vertical play.

- Wheel Bearings: Grab the tire at the 9 and 3 o’clock positions and try to rock it. If there’s play, suspect a wheel bearing. You might also hear a grinding noise when spinning the wheel.

- Track Bar: This is a bit trickier. Locate the track bar. Have your helper gently rock the steering wheel while you watch the track bar. Look for any movement at the points where it attaches to the frame and the axle. Also, try to push and pull the track bar horizontally. Any significant play at the mounting points or in the bar itself indicates an issue. Check the bolts holding it in place – they should be tight.

- Control Arm Bushings: Try to pry between the control arms and their mounting points on the frame and axle. If the bushings are worn, you’ll see significant movement.

- Steering Box: Check the steering box itself. Look for any looseness where it mounts to the frame. You can also have a helper turn the steering wheel very slightly while the engine is running, and feel for any looseness in the pitman arm connection to the steering box.

Professional Diagnosis

If you’re not comfortable performing these checks or can’t identify the issue, take your Jeep to a reputable mechanic or 4×4 shop. They have the experience and equipment to accurately diagnose the problem.

Fixing the Wobble: Your Step-by-Step Guide

Once you’ve identified the problematic component(s), it’s time for repairs.

Addressing Steering System Issues

-

Jeep Tie Rod Replacement: If your tie rod ends are worn, they need to be replaced. This is usually done by unthreading the old ends and threading on new ones. You’ll likely need to adjust the length of the tie rod to get your alignment close before a professional alignment.

- Procedure: Loosen jam nuts, unthread tie rod ends, install new ends, and thread them in to match the old ones as closely as possible. Tighten jam nuts securely.

- Important: After replacing tie rod ends, a Jeep front end alignment is absolutely crucial.

-

Jeep Steering Stabilizer: While not the root cause, if your steering stabilizer is leaking or feels weak, replace it. A new, properly functioning stabilizer will help keep your steering more settled.

- Installation: Typically involves unbolting the old unit and bolting in the new one. Ensure it’s mounted correctly and not binding.

Resolving Suspension System Problems

-

Jeep Ball Joint Replacement: This is a more involved repair. It usually requires removing the wheel, brake caliper, rotor, and then pressing out the old ball joint and pressing in the new one.

- Procedure: Disassemble wheel hub components, use a ball joint press tool to remove the old joint, clean the bore, install the new joint using the press, and reassemble everything.

- After Replacement: A Jeep front end alignment is mandatory.

-

Jeep Control Arm Bushings: Replacing worn bushings can involve pressing out old rubber and pressing in new ones. Sometimes, control arms are replaced as a complete unit if the bushings are integrated.

- Procedure: Loosen and remove the control arm, press out old bushings, clean the bores, press in new bushings (grease them well), reinstall the control arm, and torque to spec.

- After Replacement: Check and potentially adjust Jeep caster adjustment and perform a Jeep front end alignment.

-

Jeep Track Bar Repair: If the track bar itself is bent, it needs to be replaced. If the issue is with the mounting points, you might need to replace bushings, bolt kits, or in some cases, reinforce the mounting brackets on the frame or axle.

- Procedure (Bushings/Bolts): Remove the track bar, replace worn bushings or bolts, reattach the track bar, and ensure all fasteners are torqued correctly.

- After Repair: A Jeep front end alignment is usually required.

Rectifying Wheel and Tire Concerns

-

Jeep Wheel Bearing Replacement: This is another more complex repair, often involving removing the wheel hub assembly.

- Procedure: Remove wheel, brake caliper, rotor. Disassemble hub assembly. Press out old bearing, press in new bearing, and reassemble.

- After Replacement: A Jeep front end alignment is recommended.

-

Jeep Tire Balance: If your tires are out of balance, take them to a tire shop to be rebalanced. It’s a relatively inexpensive procedure.

When to Consider Suspension Upgrades

Sometimes, especially with lifted Jeeps, the stock suspension components may not be robust enough to handle the increased stress, larger tires, or off-road use. In these cases, a Jeep suspension upgrade to more heavy-duty aftermarket components might be the best long-term solution. This can include:

- Adjustable Track Bars: These allow for precise adjustment of axle position, especially important after lifting.

- Heavy-Duty Tie Rods and Drag Links: These are often thicker and stronger than stock, reducing flex and wear.

- Upgraded Ball Joints: Heavy-duty ball joints can offer more durability.

- Aftermarket Control Arms: Often built with stronger bushings and better geometry for lifted vehicles.

The Importance of a Professional Jeep Front End Alignment

Crucially, after replacing any steering or suspension components that affect wheel angles (tie rods, ball joints, drag link, track bar, steering box), a professional Jeep front end alignment is absolutely essential.

Even if you replace parts with identical stock components, their original alignment specifications may have shifted over time due to wear. A proper alignment ensures that your wheels are pointed straight, that the caster, camber, and toe are set correctly, and that the steering wheel is centered. This not only prevents premature tire wear but is also vital for eliminating the Death Wobble.

What to expect during a Jeep front end alignment:

- Wheel Camber: The vertical tilt of the wheel.

- Wheel Toe: The angle of the wheels relative to each other when viewed from above.

- Caster: The angle of the steering axis.

- Steering Wheel Centering: Ensuring the steering wheel is straight when the vehicle is going straight.

Table: Common Causes and Solutions for Death Wobble

| Symptom/Component Checked | Potential Cause | Action Needed |

|---|---|---|

| Steering wheel play | Worn tie rod ends | Jeep tie rod replacement |

| Loose steering box mounting | Tighten mounting bolts, inspect steering box | |

| Worn steering box internal gears | Jeep steering box replacement | |

| Worn drag link ends | Jeep drag link replacement | |

| Wheel wiggle (top/bottom) | Worn ball joints | Jeep ball joint replacement |

| Loose wheel bearings | Jeep wheel bearing replacement | |

| Axle shift side-to-side | Worn track bar bushings/mounts | Jeep track bar repair (bushings/bolts) |

| Bent track bar | Jeep track bar replacement | |

| Excessive bouncing | Worn shocks/struts | Shock absorber replacement |

| Worn control arm bushings | Jeep control arm bushings replacement | |

| Vibration at speed | Unbalanced tires | Jeep tire balance |

| Worn wheel bearings | Jeep wheel bearing replacement | |

| Light steering feel | Low caster angle | Jeep caster adjustment (if possible) |

Frequently Asked Questions (FAQ)

-

Q: Can a Death Wobble damage my Jeep?

A: Yes, prolonged or severe Death Wobble can cause further damage to steering and suspension components, including the steering box, ball joints, and track bar. It also makes the vehicle very dangerous to drive. -

Q: Is the Death Wobble covered by warranty?

A: It depends on your warranty and the cause. If the wobble is due to a manufacturing defect in original parts, it might be covered. However, modifications like lifts or larger tires often void any warranty on related components. -

Q: How often should I check my steering and suspension?

A: It’s a good idea to inspect your steering and suspension components regularly, especially if you do a lot of off-roading. A visual check every few thousand miles or after any significant off-road excursion is recommended. -

Q: What are the signs of a failing Jeep steering stabilizer?

A: A failing stabilizer might feel soft, allowing more steering wheel play, or it could be leaking fluid. However, as mentioned, it’s rarely the root cause of a true Death Wobble. -

Q: What is the difference between a tie rod and a drag link?

A: Both are part of the steering linkage, but they connect different points. The tie rod connects the steering knuckles to each other (or to the steering rack/box). The drag link connects one steering knuckle to the steering box’s pitman arm. They are distinct but equally important components. -

Q: How critical is caster adjustment for preventing Death Wobble?

A: Caster plays a role in steering stability. Proper caster angles help the wheels self-center. However, it’s often worn suspension parts that lead to caster issues, so while caster adjustment can help, it’s usually part of a broader solution that includes fixing worn components.

By systematically diagnosing and addressing the worn or loose components in your Jeep’s steering and suspension system, you can conquer the Death Wobble and restore confidence in your ride. Remember, safety is paramount – if you’re unsure, always consult a professional. Happy Jeeping!