What is Jeep Wrangler Death Wobble? Death Wobble is a violent, uncontrollable shaking or oscillation of the steering wheel and front end of a Jeep Wrangler, typically occurring after hitting a bump or pothole at speed. Can I fix it myself? Yes, many common causes of Death Wobble can be diagnosed and fixed by a DIY mechanic with the right tools and knowledge. Who is most affected? While most prevalent in modified Jeep Wranglers with larger tires and altered suspension, stock Wranglers can also experience this alarming phenomenon.

The dreaded “Death Wobble” is a notorious issue that can strike fear into the hearts of Jeep Wrangler owners. This violent shaking of the steering wheel and front end, often triggered by road imperfections, can make driving feel unsafe and unnerving. But fear not! While it sounds terrifying, understanding the root causes and knowing how to tackle them can bring your Jeep back to a stable, enjoyable state. This comprehensive guide will walk you through identifying and fixing the common culprits behind the Jeep Wrangler vibration that is the Death Wobble.

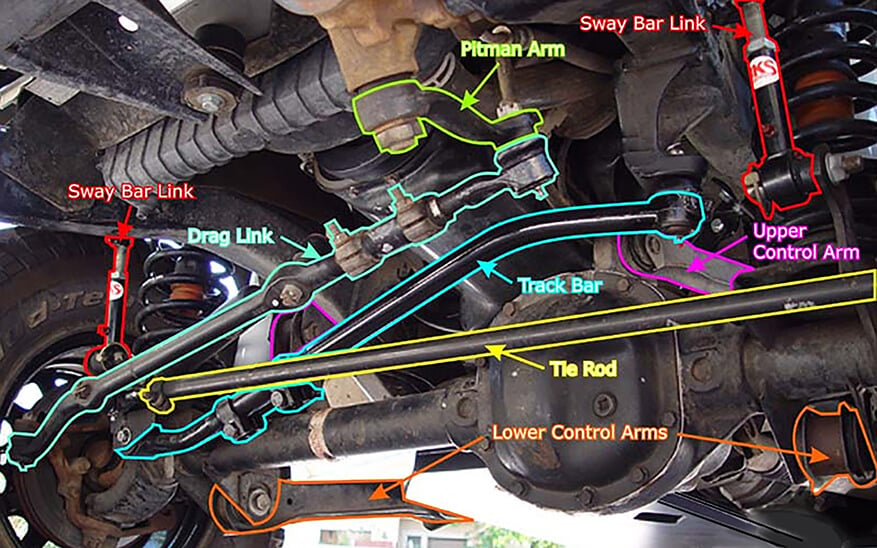

Image Source: www.quadratec.com

Deciphering the Cause: What Triggers the Jeep Steering Shimmy?

The Jeep steering shimmy, more commonly known as Death Wobble, isn’t a single, isolated failure. Instead, it’s a symptom of a larger problem within the steering and suspension system. It’s a chain reaction. When a component is worn or loose, hitting a bump can cause the front axle to oscillate rapidly. This oscillation feeds back through the steering system, causing the wheel to shake violently. Think of it like a feedback loop in an audio system – a small disturbance gets amplified into a deafening roar.

Several components in your Jeep Wrangler’s front end are critical for stable steering. When any of these parts wear out or become loose, they can initiate the dreaded wobble. The goal of fixing Death Wobble is to identify and replace or tighten these worn parts to break the oscillation cycle.

Key Components Involved in the Jeep Wrangler Vibration:

- Steering System: Tie rod ends, drag link, steering box.

- Suspension System: Ball joints, control arm bushings, track bar, shocks, springs.

- Wheels and Tires: Tire balance, wheel bearings, lug nut torque.

Diagnosing the Root of the Wobble: A Step-by-Step Approach

Before you start replacing parts, it’s crucial to accurately diagnose the source of your Jeep Wrangler vibration. A thorough inspection is your best friend here. Get under your Jeep and meticulously examine each component in the front steering and suspension.

Inspecting the Jeep Steering System:

The steering system is where the wobble is most directly felt. Loose or worn parts here will transmit that oscillation straight to your hands.

1. Jeep Tie Rod Ends:

These are arguably the most frequent culprits. Tie rod ends connect your steering knuckle to the steering box. They have a ball-and-socket design that allows for movement as you steer. Over time, the grease inside can wear out, or the socket can become loose, leading to play.

- Inspection:

- With the engine off, have a helper turn the steering wheel back and forth rapidly (just a few inches).

- Watch the tie rod ends where they connect to the steering knuckle and the drag link.

- Look for any visible movement or play in the ball joint itself. You can often feel it by trying to wiggle the tie rod end by hand.

- Check for torn rubber boots, which indicate that dirt and moisture have contaminated the joint, accelerating wear.

2. Jeep Ball Joints:

Ball joints are similar to tie rod ends, allowing the steering knuckle to pivot. They are essential for smooth steering and suspension articulation. Worn ball joints can cause excessive play and contribute significantly to Death Wobble.

- Inspection:

- Jack up the front of your Jeep so the wheels are off the ground.

- Grab the tire at the top and bottom.

- Try to rock the tire back and forth. If you feel or see movement at the ball joint (where the control arm connects to the steering knuckle), they are likely worn.

- Repeat this by grabbing the tire on the sides to check for side-to-side play, which can indicate worn wheel bearings.

3. Steering Stabilizer:

The steering stabilizer is a shock absorber for your steering system. It helps dampen minor vibrations and makes steering easier. While it doesn’t cause Death Wobble, a faulty or worn steering stabilizer can exacerbate existing issues or mask underlying problems.

- Inspection:

- Look for leaks on the stabilizer.

- With the engine off, try to push and pull the steering linkage. If the stabilizer feels excessively loose or offers no resistance, it might be worn out.

- It’s important to note that even a new, properly functioning steering stabilizer cannot fix worn-out steering and suspension components. It’s a band-aid, not a cure, for Death Wobble.

4. Steering Box:

The steering box (or steering rack on some models) translates your steering wheel movements into physical movement of the wheels. Wear within the steering box can introduce slop and play into the system.

- Inspection:

- With the engine off and the wheels on the ground, slowly turn the steering wheel back and forth.

- Observe the linkage connecting to the steering box.

- Look for excessive play between the steering wheel’s movement and the initial movement of the linkage.

- Check for fluid leaks around the steering box.

Examining the Suspension for Jeep Suspension Problems:

The integrity of your suspension components is paramount. Any looseness or wear here can allow the axle to shift and induce that terrifying oscillation.

1. Jeep Track Bar Issue:

The track bar (also known as a Panhard rod) connects the axle to the frame, preventing it from side-to-side movement. It’s a critical component for maintaining axle alignment. A worn or loose track bar, particularly at its mounting points, is a very common cause of Death Wobble.

- Inspection:

- Locate the track bar under your Jeep. It’s a solid bar connecting the driver’s side of the front axle to the frame on the passenger side.

- Check the bushings at both ends. Look for any signs of cracking, tearing, or excessive wear.

- Have a helper apply the brakes and try to rock the Jeep side-to-side (while the engine is off). Watch the track bar mounting points.

- Any noticeable movement where the track bar attaches to the axle or frame indicates a problem. Check the bolts securing the track bar; they should be tight.

2. Control Arm Bushings:

Control arms connect the axle to the frame, controlling axle articulation and alignment. The bushings at the ends of these arms absorb shock and vibration. Worn bushings can lead to significant play.

- Inspection:

- Inspect the rubber bushings at the ends of all four control arms.

- Look for cracking, tearing, or if the metal sleeve has separated from the rubber.

- Try to wiggle the control arms themselves to detect play.

3. Wheel Bearings:

While not directly part of the steering linkage, worn wheel bearings can cause play in the wheel assembly, mimicking some symptoms of Death Wobble or contributing to it.

- Inspection:

- With the front wheels jacked up, grab the tire at the 3 o’clock and 9 o’clock positions.

- Try to wiggle the tire. If you feel any play, it indicates a potential wheel bearing issue.

4. Shocks and Springs:

Damaged or worn shocks and springs can affect how the suspension absorbs impacts. While less common as a primary cause of Death Wobble, they can contribute to overall instability.

- Inspection:

- Visually inspect shocks for leaks.

- Check if springs are seated correctly and not broken.

Wheel and Tire Considerations:

Don’t overlook the simplest things! Improperly balanced tires or loose lug nuts can also create vibrations that might be mistaken for Death Wobble.

1. Tire Balance:

Improperly balanced tires can cause vibrations, especially at certain speeds.

- Inspection:

- If you suspect tire balance, consider having them professionally balanced.

- Look for missing wheel weights.

2. Lug Nut Torque:

Loose lug nuts are a serious safety hazard and can cause wheel wobble.

- Inspection:

- Check that all lug nuts on all wheels are torqued to the manufacturer’s specifications.

The Jeep Shimmy Fix: Tackling the Wobble Head-On

Once you’ve identified the worn components, it’s time for the Jeep shimmy fix. The strategy is to replace or repair the faulty parts to restore proper alignment and eliminate play.

Replacing Worn Tie Rod Ends:

This is a common and often effective fix for Death Wobble.

- Tools Needed: Tie rod end puller (pickle fork), adjustable wrenches, torque wrench, jack stands, lug wrench, penetrating oil.

- Procedure:

- Loosen lug nuts on the wheel.

- Jack up the Jeep and support it securely on jack stands.

- Remove the wheel.

- Apply penetrating oil to the tie rod end castle nut and the threaded shaft.

- Remove the cotter pin and the castle nut.

- Use a tie rod end puller (or a pickle fork) to separate the tie rod end from the steering knuckle. Be prepared for a sudden release of tension.

- Unthread the old tie rod end from the drag link.

- Thread the new tie rod end onto the drag link, adjusting it to match the length of the old one as closely as possible. This helps maintain roughly correct alignment.

- Connect the new tie rod end to the steering knuckle and install a new castle nut and cotter pin.

- Tighten the castle nut to the specified torque and ensure the cotter pin slots align.

- Reinstall the wheel and torque the lug nuts.

- Repeat for the other side if necessary.

Replacing Worn Ball Joints:

Ball joint replacement is a more involved process and often requires specialized tools.

- Tools Needed: Ball joint press kit, heavy-duty jack, jack stands, breaker bar, sockets, torque wrench, hammer, large adjustable wrench.

- Procedure:

- Similar to tie rod end replacement, jack up the Jeep and remove the wheel.

- Remove the brake caliper and rotor to access the ball joints.

- Use a ball joint press kit to press out the old ball joints from the steering knuckle. This typically involves separating the knuckle from the control arms.

- Clean the knuckle bore where the ball joint sits.

- Use the ball joint press kit to press in the new ball joints. Ensure they are seated correctly and straight.

- Reassemble the steering knuckle, control arms, rotor, and caliper.

- Install the wheel and torque lug nuts.

Addressing a Jeep Track Bar Issue:

If your track bar bushings are worn or the mounting holes are enlarged, replacement or reinforcement is necessary.

- Options:

- Replace Bushings: If only the bushings are worn, you can often press out the old ones and press in new ones.

- Replace Track Bar: If the track bar itself is bent or the mounting points are damaged, replacing the entire track bar is recommended. Many aftermarket track bars offer improved strength and adjustability, which can be beneficial for modified Jeeps.

- Reinforce Mounting Points: If the frame or axle mounting holes are elongated, you might need to reinforce them with welding or oversized hardware.

Replacing the Steering Stabilizer:

While not a cure, a worn steering stabilizer should be replaced to ensure proper function of the steering system.

- Procedure:

- Locate the steering stabilizer.

- Remove the mounting bolts or clamps securing the old stabilizer.

- Carefully remove the old stabilizer.

- Install the new stabilizer, ensuring it’s properly aligned.

- Tighten the mounting bolts or clamps to the specified torque.

Crucial Next Steps After Repairs: Jeep Wheel Alignment and Verification

After you’ve replaced worn parts, it is absolutely essential to get a professional Jeep wheel alignment. Replacing tie rod ends, ball joints, or track bars will change your Jeep’s alignment, affecting steering and tire wear.

Why a Jeep Wheel Alignment is Necessary:

- Restores Proper Steering Geometry: Ensures your wheels are pointed straight and at the correct angles relative to each other and the road.

- Prevents Uneven Tire Wear: Misaligned wheels can cause tires to wear out quickly and unevenly.

- Improves Handling and Stability: A proper alignment will make your Jeep track straight and predictable.

Post-Repair Verification:

- Test Drive: After the alignment, take your Jeep for a test drive on a safe stretch of road. Start at lower speeds and gradually increase.

- Listen and Feel: Pay attention to any residual vibrations or unusual noises.

- Check Again: If the Death Wobble persists, it’s time for a deeper dive into other potential causes or a re-evaluation of the parts you replaced.

Advanced Considerations and Aftermarket Upgrades

For Jeep owners who frequently encounter Death Wobble, especially after modifications like larger tires or suspension lifts, considering aftermarket upgrades can provide a more robust and durable solution.

Upgraded Track Bars:

Adjustable and heavy-duty track bars are a popular upgrade. They offer better strength and allow for fine-tuning of axle position, especially after lifting the Jeep.

Heavy-Duty Tie Rods and Drag Links:

Aftermarket steering components made from stronger materials can withstand more abuse and are less prone to wear.

High-Performance Steering Stabilizers:

While not a cure, a high-quality steering stabilizer can provide better damping and longevity.

Steering Box Braces:

These braces reinforce the steering box mounting points, reducing flex and potential for looseness.

Preventing Future Jeep Wrangler Vibration Issues:

- Regular Inspections: Make it a habit to inspect your steering and suspension components regularly, especially after off-roading.

- Proper Maintenance: Keep your Jeep clean, especially the undercarriage, to prevent dirt and debris from accelerating wear.

- Cautious Driving: Avoid hitting potholes and obstacles at high speeds whenever possible.

- Mindful Modifications: If you lift your Jeep or install larger tires, be aware of the increased stress on your steering and suspension components. Consider upgrading parts proactively.

Frequently Asked Questions (FAQ)

Q1: How often should I check my Jeep’s steering and suspension?

A1: It’s a good idea to perform a visual inspection every oil change. A more thorough check should be done at least every 6 months or after significant off-road use.

Q2: Can a loose lug nut cause Death Wobble?

A2: While a loose lug nut primarily causes wheel wobble and potential wheel detachment, it can contribute to vibrations that might be perceived as or worsen a Death Wobble. Always ensure lug nuts are torqued correctly.

Q3: My Jeep still wobbles after replacing the tie rod ends. What next?

A3: If replacing tie rod ends didn’t solve the issue, the next most likely culprits are worn ball joints or a Jeep track bar issue. A thorough re-inspection is needed.

Q4: Is it safe to drive with Death Wobble?

A4: No, it is not safe to drive with Death Wobble. The uncontrolled shaking can make it very difficult to steer and could lead to a loss of control. Address the issue immediately.

Q5: Do I need to replace both sides if one tie rod end is bad?

A5: It’s highly recommended to replace tie rod ends in pairs. If one is worn, the other is likely not far behind. This ensures balanced steering and longevity.

Q6: Can a Jeep steering stabilizer fix Death Wobble?

A6: No, a steering stabilizer is not a fix for Death Wobble. It’s a dampener. Death Wobble is caused by worn mechanical components in the steering and suspension system. A stabilizer can help mitigate minor vibrations but will not cure the underlying problem.

Q7: What is a Jeep track bar issue?

A7: A Jeep track bar issue refers to wear or damage in the track bar itself or its mounting points (bushings or bolts). This component ensures the axle stays centered and prevents side-to-side movement, so any looseness can directly lead to Death Wobble.

Q8: How do I perform a Jeep ball joint test?

A8: With the front wheels off the ground, grab a tire at the top and bottom and try to rock it. Significant play or movement at the ball joint connection point indicates wear.

Q9: What are the signs of worn Jeep tie rod ends?

A9: Signs include play in the steering wheel, a clunking noise when turning, or visible looseness when inspecting the tie rod ends themselves.

Q10: After fixing the wobble, do I need a Jeep wheel alignment?

A10: Yes, absolutely. Any work done on the steering linkage or suspension components will affect your Jeep’s alignment and requires a professional alignment to ensure proper steering, handling, and tire wear.

By systematically diagnosing and addressing the worn components, you can effectively perform a Jeep shimmy fix and enjoy a stable, confident driving experience in your Jeep Wrangler once again. Remember, safety first, and don’t hesitate to consult a qualified mechanic if you’re unsure about any step of the process.