What is Jeep Wrangler death wobble? Can I fix it myself? Who is affected by death wobble? Jeep Wrangler death wobble is a violent, rapid shaking of the steering wheel and front end of your Jeep, typically occurring at speeds between 35-55 mph, especially after hitting a bump or pothole. Yes, you can often fix it yourself with careful diagnosis and component replacement. It primarily affects Jeep Wranglers, but can also occur in other solid axle vehicles if their steering and suspension components are worn or improperly installed.

Death wobble can be a scary and dangerous experience, turning your beloved Jeep into a bucking bronco. This guide will walk you through the common causes of this phenomenon and provide actionable steps to get your Jeep tracking straight and stable again.

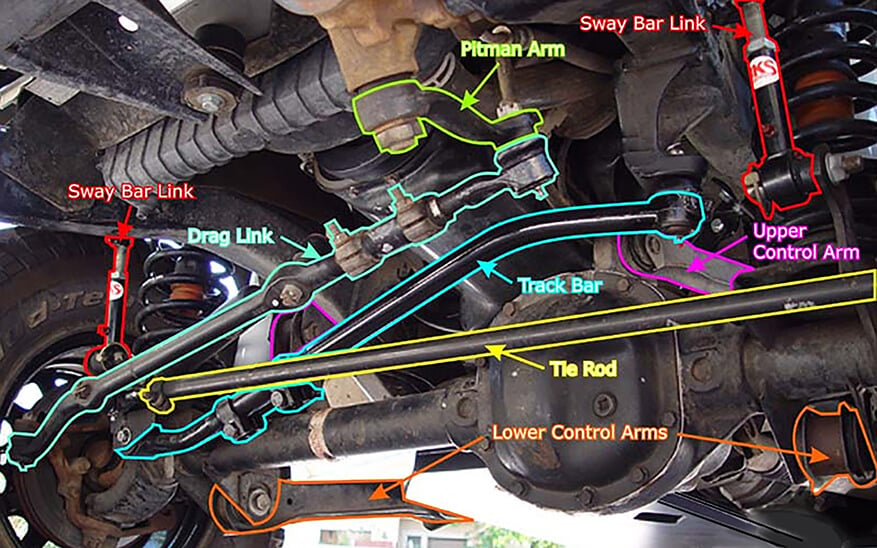

Image Source: www.quadratec.com

Deciphering the Root Causes of Death Wobble

Death wobble isn’t caused by a single faulty part; it’s usually a chain reaction. When one or more suspension components develop play or looseness, they can amplify vibrations. These vibrations can then feed back through the steering system, rapidly oscillating and creating the characteristic wobble. Think of it like a domino effect where the initial nudge of a worn part leads to a cascade of instability.

Here are the most common culprits:

- Loose or Worn Steering Components:

- Tie Rod Ends: These connect your steering knuckle to the steering box. If they’re worn, they allow for independent movement that can trigger wobble.

- Drag Link: This connects the steering arm on one knuckle to the steering box. Wear here can also introduce play.

- Steering Stabilizer: While not the cause of death wobble, a worn or weak steering stabilizer can fail to dampen the vibrations, allowing them to escalate.

- Front Axle and Suspension Issues:

- Ball Joints: These are crucial pivot points in your steering knuckle. Worn ball joints allow the wheel to move in unintended directions, contributing to instability.

- Track Bar: This vital component keeps your front axle centered under the Jeep. A loose or bent track bar allows the axle to shift side-to-side, which is a primary driver of death wobble.

- Control Arms: These connect the axle to the Jeep’s frame. Worn bushings in the control arms allow for excessive movement, impacting axle alignment.

- Wheel Bearings: While less common, severely worn wheel bearings can introduce play that contributes to wobble.

- Tire and Wheel Problems:

- Improper Tire Balance: Unbalanced tires can cause vibrations that, under the right conditions, can trigger death wobble.

- Uneven Tire Wear: Tires with irregular wear patterns can create their own imbalances and affect how the Jeep tracks.

- Bent Wheel or Rim: A bent wheel can cause a constant imbalance.

- Loose Lug Nuts: Critically important, loose lug nuts can allow the wheel to shift on the hub.

A Step-by-Step Diagnostic Approach

Before you start replacing parts, it’s crucial to perform a thorough inspection. This will help you pinpoint the exact problem and avoid unnecessary expenses.

Step 1: Visual Inspection – Get Under Your Jeep

Safety first! Use jack stands to securely support your Jeep. Never rely solely on a jack. Get a flashlight and meticulously examine the following components.

Inspecting Steering Components

-

Tie Rod Ends and Drag Link:

- Grab the tie rod ends and try to wiggle them up and down and side-to-side. Any play indicates wear.

- Check the drag link similarly. The joints should be tight.

- Look for torn or damaged boots on the tie rod ends and drag link. This allows dirt and water in, accelerating wear.

-

Steering Stabilizer:

- Check for leaks.

- Push and pull on the stabilizer rod. It should offer firm resistance in both directions. If it feels weak or loose, it needs replacing.

- Inspect its mounting brackets for cracks or looseness.

Inspecting Front Axle and Suspension

-

Ball Joints:

- With the front wheels on the ground (this puts weight on the ball joints), try to lift and lower the steering knuckle by prying under the tire. Any up-and-down movement of the knuckle relative to the axle housing indicates worn ball joints.

- You can also have a helper gently rock the steering wheel back and forth while you observe the ball joint area for movement.

-

Track Bar:

- This is a critical component. Locate the track bar, which runs diagonally from the frame to the axle.

- Check the mounting bolts at both ends. They should be tight.

- With a pry bar, try to move the track bar side-to-side at its mounting points on the axle and frame. Significant movement means the bushings or the bar itself is worn or bent.

- Inspect the track bar for any signs of bending, especially if you have lifted your Jeep.

-

Control Arms:

- Inspect the rubber bushings at both ends of the upper and lower control arms. Look for cracking, tearing, or extrusion, which indicates they are worn out.

- With a pry bar, try to move the control arms. There should be minimal play.

-

Wheel Bearings:

- With the wheel off the ground, grab the tire at the top and bottom and try to wiggle it. There should be no play. If there is, the wheel bearing may be the culprit.

Inspecting Tires and Wheels

- Tire Condition:

- Check your tires for uneven wear patterns (cupping, feathering, balding).

- Inspect for any damage, bulges, or embedded objects.

- Wheel Condition:

- Ensure no wheels are visibly bent or damaged.

- Lug Nuts:

- Verify all lug nuts are tight. The correct lug nut torque is essential for preventing wheel wobble.

Step 2: The “Wiggle Test” – Isolating the Play

This is where you actively try to replicate the wobble or identify the specific part that moves excessively.

Steering Wheel Wiggle Test

- Secure the Jeep: Ensure your Jeep is safely supported on jack stands with the front wheels off the ground.

- One Person Operation: Have one person sit in the Jeep and gently rock the steering wheel back and forth, but not enough to turn the wheels.

- Inspect Components: While the steering wheel is being moved, another person should get under the Jeep with a flashlight and carefully observe all the steering and front suspension components (tie rod ends, drag link, ball joints, track bar, steering box) for any signs of movement or play.

- Pinpoint the Source: The component that moves first or most noticeably is often the problem area. For example, if the tie rod end joint is visibly loose as the steering wheel is rocked, that’s likely your issue.

Axle Wiggle Test

- Front Wheels Off the Ground: Ensure the Jeep is securely on jack stands.

- Grab and Shake: Grab a tire at the 10 o’clock and 2 o’clock positions. Try to wiggle the tire in and out.

- Observe Movement: Watch the track bar and ball joints while doing this. Excessive play in the ball joints will cause the knuckle to move independently of the axle. Excessive play in the track bar mounts or the bar itself will allow the axle to shift under the Jeep as you move the tire.

Common Fixes for Death Wobble

Once you’ve identified the problematic component(s), it’s time to address them.

Replacing Worn Steering Components

-

Tie Rod Ends & Drag Link:

- These are usually replaced as a set.

- You’ll need a pickle fork or tie rod end puller to separate them from the steering knuckle.

- Be prepared for a potentially involved process, especially if the components are seized.

- After replacement, a wheel alignment is absolutely critical.

-

Steering Stabilizer:

- This is often the easiest fix.

- Simply unbolt the old stabilizer and bolt on the new one.

- Ensure you get a heavy-duty steering stabilizer, especially if you have larger tires or plan on off-roading.

Addressing Front Axle and Suspension Issues

-

Ball Joints:

- Replacing ball joints is a more labor-intensive job.

- It typically involves removing the knuckle, pressing out the old ball joints, and pressing in new ones.

- Specialized tools are often required.

- After ball joint replacement, a wheel alignment is mandatory.

-

Track Bar:

- If the track bar itself is bent or the bushings are worn, it needs replacement.

- Ensure you get a quality replacement, preferably an adjustable one if you have a lift kit, to ensure proper axle centering.

- If you’re lifting your Jeep, an aftermarket, adjustable track bar is highly recommended to maintain proper geometry and prevent death wobble.

- Tighten the track bar mounting bolts to the manufacturer’s specified lug nut torque (or equivalent for track bar bolts, typically very high).

-

Control Arms:

- If the control arm bushings are bad, you can sometimes replace just the bushings, but often it’s easier and more effective to replace the entire control arm.

- Again, aftermarket adjustable control arms are beneficial for lifted Jeeps to correct caster and pinion angles.

- Proper tightening of control arm bolts is crucial.

-

Wheel Bearings:

- Replacing wheel bearings can range from a simple press-in job to a full hub assembly replacement, depending on your Jeep model.

- This usually requires specialized tools.

Tire and Wheel Solutions

- Tire Balance:

- Have your tires professionally balanced. This is often overlooked but can be a significant contributor.

- Ensure the shop uses the correct weights for your wheel type.

- Tire Rotation and Replacement:

- If your tires are significantly worn or have uneven wear, consider rotating them or replacing them altogether.

- Wheel Hub and Lug Nut Check:

- Double-check the lug nut torque on all wheels.

- Inspect wheel hubs for any damage that might prevent proper wheel seating.

Crucial Follow-Up Steps

Wheel Alignment

This is not optional! After any work on your steering or suspension components (tie rods, drag link, ball joints, control arms, track bar), a professional wheel alignment is essential. A proper alignment ensures your wheels are pointed correctly, which is vital for stable driving and preventing premature tire wear.

Tire Balance Revisited

Even if you think your tires are balanced, it’s a good idea to have them re-checked after fixing other issues. Sometimes the vibrations from a worn component can mask a mild tire imbalance, and fixing the wobble might reveal the tire issue.

Regular Maintenance Checks

The best way to prevent death wobble is through diligent maintenance.

Key Maintenance Points

- Periodic Inspections: Regularly inspect your steering and suspension components for wear and tear.

- Tighten Lug Nuts: Always ensure your lug nut torque is correct after any wheel work.

- Grease Fittings: If your Jeep has greasable suspension components, keep them properly greased.

- Monitor Tire Wear: Keep an eye on your tire wear patterns.

- Steering Stabilizer Health: Don’t neglect your steering stabilizer. Replace it if it shows signs of weakness or leaks.

When to Seek Professional Help

While many death wobble fixes are DIY-friendly, some repairs require specialized tools and expertise. If you’re uncomfortable with any of these steps, or if the problem persists after your initial repairs, don’t hesitate to take your Jeep to a qualified mechanic. They have the experience and equipment to diagnose and fix even the most stubborn issues.

Frequently Asked Questions (FAQ)

Q1: My Jeep is lifted, does that make death wobble more likely?

A1: Yes, lifting a Jeep can exacerbate existing wear in suspension components and can also introduce new stress points. Proper geometry correction with adjustable control arms and a quality track bar is crucial for lifted Jeeps to prevent death wobble.

Q2: Can a bad steering stabilizer cause death wobble?

A2: No, a bad steering stabilizer doesn’t cause death wobble, but it fails to prevent it. It’s designed to dampen oscillations. If other components are worn, a bad stabilizer won’t stop the wobble from happening.

Q3: How much does it cost to fix death wobble?

A3: The cost can vary greatly depending on what parts need replacing. It can range from under $100 for a steering stabilizer to several hundred or even over a thousand dollars if multiple ball joints, tie rods, and the track bar need replacement, including labor if you take it to a shop.

Q4: I replaced my steering stabilizer, but the wobble is still there. What else could it be?

A4: The steering stabilizer is often the last line of defense. If it didn’t fix the wobble, the problem lies deeper within your steering or suspension components like ball joints, tie rod ends, or the track bar. You’ll need to perform a more thorough inspection.

Q5: Is death wobble covered by warranty?

A5: Typically, death wobble caused by normal wear and tear on components is not covered by the factory warranty, especially on older Jeeps. However, if the issue stems from a manufacturing defect or improper installation of aftermarket parts, there might be coverage. It’s best to check your specific warranty details.

Q6: Will changing tire size cause death wobble?

A6: Significantly larger tires can put more stress on steering and suspension components, potentially accelerating wear and making death wobble more likely if those components are already worn or marginal. It also changes the vehicle’s geometry, which might require adjustments to components like the track bar or steering stops.

By systematically diagnosing and addressing the potential causes, you can get your Jeep Wrangler back to its stable and enjoyable driving state. Happy Jeeping!