What is death wobble in a Jeep? Death wobble is a violent, uncontrollable shaking or shimmy of the steering wheel that occurs at certain speeds, often after hitting a bump or pothole. Can I fix death wobble myself? Yes, with the right tools and knowledge, many Jeep owners can diagnose and fix death wobble. Who is responsible for death wobble? Usually, worn or loose steering and suspension components are the culprits behind death wobble.

This notorious phenomenon, affectionately (or perhaps fearfully) known as “death wobble,” is a terrifying experience for any Jeep owner. It’s more than just an annoying vibration; it’s a violent oscillation that can seize control of your steering wheel, making your Jeep feel like it’s trying to shake itself apart. If you’ve experienced it, you know the sheer panic it induces. If you haven’t, consider this your comprehensive guide to preventing and curing it. This article dives deep into Jeep death wobble causes, how to identify them, and the most effective ways to fix them, turning your terrifying rides into smooth adventures.

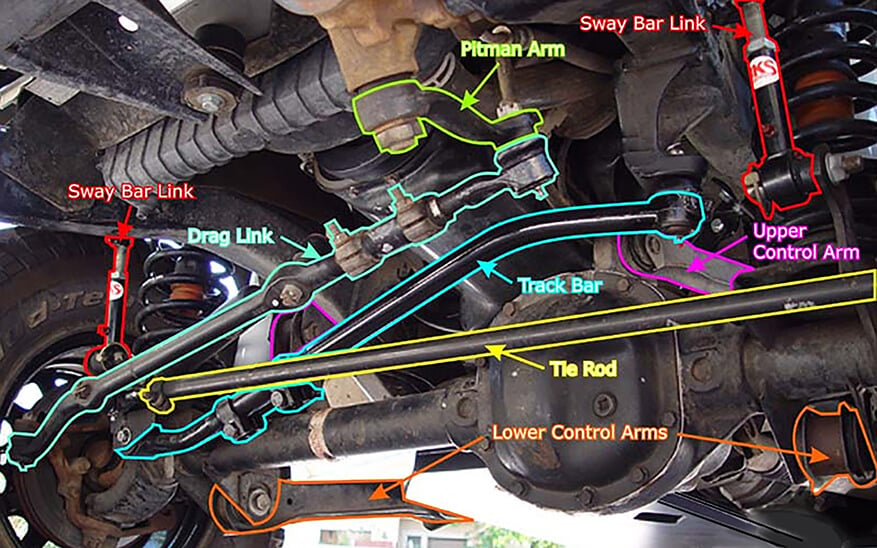

Image Source: www.quadratec.com

Pinpointing the Root Causes of Jeep Death Wobble

Death wobble isn’t a single, isolated failure. Instead, it’s a symptom of a chain reaction within your Jeep’s steering and suspension system. A slight imbalance or wear in one component can create excessive play, which is then amplified by others, leading to that terrifying oscillation. Fathoming the interconnectedness of these parts is key to a lasting fix.

Several key areas are commonly implicated:

- Loose or Worn Steering Components: This is the most frequent culprit. Think of your steering system as a complex series of linkages. If any of these linkages have too much play, the steering wheel can move rapidly back and forth.

- Suspension Issues: The forces transmitted from the road through your tires are absorbed and managed by your suspension. When suspension parts are worn or misaligned, they can’t properly control these forces, contributing to the wobble.

- Tire Problems: Even seemingly minor tire issues can trigger or exacerbate death wobble.

Let’s break down the specific components that are most often at fault.

Deciphering Steering System Vulnerabilities

Your Jeep’s steering system is designed for precise control. When parts wear out, this precision is lost, and that’s where death wobble often begins.

The Crucial Role of the Jeep Steering Stabilizer

Many people think a Jeep steering stabilizer is the cure for death wobble. While a new and properly functioning steering stabilizer can help dampen the symptoms and provide a bit of extra resistance, it is not a fix for the underlying problem. Think of it as a band-aid. It can make the wobble less severe, but it won’t stop it if a critical steering component is truly worn out.

- What it does: A steering stabilizer is a shock absorber for your steering. It resists sudden movements of the steering wheel.

- Why it’s not a fix: It doesn’t correct play in the actual steering linkage. If your tie rod ends are loose, for example, the stabilizer can’t make them tight again.

- When it’s important: A worn or leaking steering stabilizer can contribute to the problem by not providing adequate damping. Replacing a faulty one is often a necessary step in the overall repair process.

Examining Jeep Tie Rod Ends

Jeep tie rod ends are critical pivot points that connect your steering knuckles to the steering gear. They allow your wheels to turn.

- How they fail: Over time, the ball joint within the tie rod end wears out. This creates a gap or “slop” in the connection.

- The impact: When you hit a bump, this slack allows the steering wheel to move erratically, which then forces the opposite tie rod end to move, and so on. This back-and-forth motion is the hallmark of death wobble.

- Checking for wear:

- With the engine off, have a helper turn the steering wheel back and forth slightly.

- Observe the tie rod ends. Any noticeable up-and-down or side-to-side play in the ball joint indicates wear.

- You can also try lifting the front tire off the ground and wiggling it. Significant play that translates directly to tie rod end movement confirms a problem.

The Function of the Drag Link

The drag link is another crucial steering linkage that connects your steering box or steering gear to one of your steering knuckles.

- How it fails: Similar to tie rod ends, the ball joint on the drag link can wear out, creating play.

- The consequence: This play directly affects the steering angle and can contribute to the wobble initiated by other worn components.

- Checking for wear: The method is similar to checking tie rod ends. With the wheels on the ground, have a helper turn the steering wheel gently while you observe the drag link ends for play.

Steering Box and Pitman Arm

The steering box translates the rotation of your steering wheel into the movement of your wheels. The Pitman arm attaches to the steering box and connects to the drag link.

- Wear points: The steering box itself can develop internal wear, leading to looseness. The connection between the Pitman arm and the steering box can also become loose, as can the ball joint on the Pitman arm where it connects to the drag link.

- Symptoms of wear: Excessive free play in the steering wheel before the wheels begin to turn is a common indicator of steering box wear.

- Inspection: Check for any looseness where the Pitman arm connects to the steering box, and also for play in the Pitman arm ball joint.

Investigating Jeep Suspension Issues

Beyond the direct steering linkages, the broader Jeep suspension issues play a significant role in maintaining stability.

The Critical Role of the Jeep Track Bar

The track bar (also known as a Panhard rod) is a vital component that prevents your front axle from shifting side-to-side relative to your Jeep’s frame. It’s essentially a rigid bar connecting the axle to the chassis at two points.

- How it causes wobble: The ends of the track bar attach to the axle and the frame via bushings or ball joints (depending on the Jeep model). If these connection points wear out or become loose, the axle can move laterally. This lateral movement is a primary driver of death wobble.

- Why a Jeep track bar replacement is often needed: When the track bar bushings or ball joints wear, they allow the axle to “steer” itself independently of the steering wheel, causing that violent shimmy.

- Inspection:

- With the front tires on the ground, have a helper turn the steering wheel back and forth gently.

- Watch the track bar ends where they attach to the frame and the axle. Any significant movement in these bushings or ball joints indicates a problem.

- Another method is to try and move the axle side-to-side while the Jeep is stationary. Excessive movement points to track bar issues.

Worn Ball Joints

Ball joints are crucial pivot points in your front suspension, allowing your wheels to articulate for steering and absorb road imperfections.

- The effect of wear: Worn ball joints create excessive play in the steering knuckle assembly. When the tire hits a bump, this play allows the knuckle to pivot erratically, transmitting forces back through the steering system. This can easily initiate or worsen death wobble.

- Checking for wear:

- Jack up the front of your Jeep so the wheels are off the ground.

- With the steering wheel locked (or the vehicle in gear and parking brake engaged), try to push and pull the top of the tire. If there’s significant in-and-out play at the top, your ball joints are likely worn.

- You can also place a pry bar under the tire and lift gently. Play in the ball joint will manifest as movement in the tire’s position.

- Jeep ball joint replacement is a common fix for death wobble.

Wheel Bearings

While less common as a primary cause, severely worn wheel bearings can introduce enough play to contribute to or amplify death wobble.

- How they contribute: Loose wheel bearings allow the wheel hub to wobble, which in turn can affect steering and suspension dynamics.

- Checking for wear: With the wheels off the ground, grab the tire at the top and bottom and try to wiggle it. If you feel play or hear grinding, the wheel bearings may be the issue.

Other Suspension Components

Other worn suspension parts can also play a role:

- Control Arm Bushings: If the bushings in your control arms are worn, they allow for excessive movement of the axle relative to the frame, impacting steering stability.

- Shock Absorbers: While not a direct cause, blown or worn-out shock absorbers fail to dampen oscillations, allowing them to persist and worsen.

Tire and Wheel Considerations

Don’t overlook the parts that actually contact the road!

The Importance of Jeep Tire Balance

An imbalanced tire can create a vibration that, at certain speeds, can resonate with other loose components in the steering and suspension system, triggering death wobble.

- What is imbalance? Tires aren’t perfectly uniform in weight. Imbalance causes a heavier spot on the tire/wheel assembly to “hop” as it rotates.

- Signs of imbalance: Vibrations in the steering wheel or seat that increase with speed.

- The solution: Proper Jeep tire balance is crucial. Get them balanced by a reputable shop, ensuring the weights are applied correctly.

Tire Condition and Pressure

- Uneven wear: Severely uneven tire wear can contribute to instability.

- Tire pressure: While less likely to cause true death wobble, significantly under-inflated tires can make steering feel vague and contribute to general instability. Ensure your tires are inflated to the manufacturer’s recommended pressure.

- Tire damage: Damaged tires or wheels (bent rims) can also introduce imbalances.

Diagnosing the Wobble: A Step-by-Step Approach

Pinpointing the exact cause can be a process of elimination. Here’s a systematic way to diagnose the issue.

Initial Checks: What You Can Do Easily

Before you start pulling parts, perform some basic checks.

- Visual Inspection:

- Look for obvious signs of damage or wear on all steering and suspension components. Check for torn boots, leaking shocks, or loose-looking connections.

- Inspect your tires for abnormal wear patterns or damage.

- Shake Test (Wheels Off the Ground):

- Safely jack up the front of your Jeep.

- With the steering wheel locked or the Jeep in park/gear, grab a tire at the 12 o’clock and 6 o’clock positions and try to wiggle it. Significant play indicates worn ball joints or possibly wheel bearings.

- Grab a tire at the 9 o’clock and 3 o’clock positions and try to turn it in and out. Play here directly points to loose tie rod ends or steering box issues.

- Wiggle Test (With a Helper):

- Have a friend gently rock the steering wheel back and forth (engine off).

- Observe all the connection points in the steering linkage, from the steering column to the tie rods, for any movement.

- Simultaneously, check the track bar ends for any lateral play where they attach to the axle and frame.

Advanced Diagnostics: Getting Underneath

This is where you’ll likely find the smoking gun.

- Track Bar Check: This is paramount. Have your helper jiggle the steering wheel. Watch the track bar bushings/ball joints. If there’s any noticeable movement at either end of the track bar, this is a prime suspect.

- Tie Rod End Check: With the wheels on the ground, have your helper turn the steering wheel slightly back and forth. Observe the tie rod ends where they connect to the steering knuckles and the drag link.

- Pitman Arm and Drag Link Check: Feel for play in the ball joint of the Pitman arm and the drag link.

- Steering Box Check: Inspect the steering box for leaks or looseness where the Pitman arm attaches. You can also check for excessive play in the steering column itself.

Table 1: Diagnostic Checklist for Death Wobble

| Component | How to Check | Likely Problem if Play is Found |

|---|---|---|

| Tie Rod Ends | Wheels on ground, helper turns steering wheel; observe ends for movement. | Loose or worn tie rod ends. |

| Drag Link Ends | Wheels on ground, helper turns steering wheel; observe drag link ball joints. | Loose or worn drag link ball joints. |

| Track Bar Ends | Helper turns steering wheel; observe track bar bushings/ball joints for movement. | Loose or worn track bar bushings/ball joints. |

| Ball Joints | Wheels off ground; grab tire at 12 & 6 o’clock and wiggle. | Worn upper or lower ball joints. |

| Wheel Bearings | Wheels off ground; grab tire at 12 & 6 o’clock and wiggle. | Worn wheel bearings. |

| Steering Box | Check for looseness where Pitman arm connects; check for play in steering column. | Worn steering box or loose Pitman arm connection. |

| Tires | Inspect for uneven wear, damage, or improper inflation. | Imbalance, damage, or improper inflation can contribute. |

| Steering Stabilizer | Inspect for leaks or damage; check resistance when pushed/pulled. | A faulty stabilizer can worsen symptoms but isn’t the root cause. |

The Path to a Wobble-Free Jeep: Repair and Upgrade Strategies

Once you’ve identified the problematic component(s), it’s time for action. Addressing the worn part is essential.

Addressing Worn Steering Components

This is often the most direct way to stop death wobble in a Jeep.

- Jeep Tie Rod End Replacement:

- This involves removing the old tie rod ends and installing new ones. It’s critical to ensure proper alignment after this job.

- Consider upgrading to heavy-duty tie rod ends for greater durability.

- Jeep Track Bar Replacement:

- If your track bar bushings or ball joint are worn, replacing the entire track bar assembly is usually the best approach.

- Many aftermarket track bars offer improved strength and adjustability, which can be beneficial, especially for lifted Jeeps.

- Drag Link and Pitman Arm:

- If the ball joints on these components are worn, they will need to be replaced. In some cases, you might replace the entire drag link assembly.

- Upgraded steering components can significantly enhance robustness.

Repairing Suspension Issues

- Jeep Ball Joint Replacement:

- This is a more involved job, often requiring special tools to press out the old ball joints and press in the new ones.

- If your ball joints are worn, it’s often recommended to replace both the upper and lower ball joints on both sides to ensure even wear.

- Wheel Bearing Replacement:

- Depending on your Jeep model, wheel bearings can be sealed units that require replacing the entire hub assembly, or they can be pressed in.

The Role of Jeep Alignment

A proper Jeep alignment is absolutely critical after any steering or suspension work.

- Why it matters: Changing tie rod ends or adjusting the track bar alters your Jeep’s steering geometry. Without a proper alignment, you’ll experience poor handling, uneven tire wear, and potentially continued steering issues.

- What to check: Ensure your alignment shop checks caster, camber, and toe. For lifted Jeeps, caster angles can be particularly important for steering stability.

Tires and Balance: The Finishing Touches

- Jeep Tire Balance:

- If tire imbalance was identified, ensure all four tires are balanced.

- Consider road-force balancing for optimal results, especially with larger off-road tires.

- Tire Condition:

- If tires are old, worn unevenly, or damaged, consider replacing them. The investment in new, quality tires can be well worth it.

Upgrading Your Steering for Longevity

While fixing the immediate problem is crucial, consider how you can prevent it from happening again. A Jeep steering upgrade can provide significant benefits.

- Heavy-Duty Steering Linkages: Aftermarket tie rod ends, drag links, and track bars are often built with stronger materials and better joint designs, making them more resistant to wear and bending.

- Adjustable Track Bars: For lifted Jeeps, an adjustable track bar allows you to precisely center the axle under the vehicle, which is essential for proper steering geometry and preventing wobble.

- Steering Box Braces and Reinforcements: Some aftermarket products can reinforce the steering box mounting points, reducing flex and improving steering response.

Table 2: Common Upgrades for Enhanced Steering Stability

| Upgrade Type | Benefits | When to Consider |

|---|---|---|

| Heavy-Duty Tie Rods | Increased strength, better joint durability, reduced flex. | After replacing stock tie rods, or for aggressive use. |

| Adjustable Track Bar | Precise axle centering, improved steering geometry, essential for lifts. | Any Jeep with a lift kit, or if stock is worn. |

| Upgraded Drag Link | Stronger construction, better joint articulation. | If stock drag link shows wear, or for heavy use. |

| Steering Stabilizer | Dampens minor oscillations, improves feel. | Always a good addition, but not a fix for worn parts. |

| Steering Box Brace | Reduces flex, improves steering feel and durability. | For Jeeps experiencing steering box stress or wear. |

Preventing Future Wobbles: Proactive Maintenance

The best way to deal with death wobble is to prevent it from occurring in the first place.

- Regular Inspections: Make it a habit to inspect your steering and suspension components regularly, especially if you off-road.

- Address Minor Play: Don’t ignore small amounts of play in your steering. These are early warning signs that a component is starting to wear.

- Proper Tire Maintenance: Keep your tires properly inflated and balanced.

- Torque Specifications: When working on your Jeep, always use a torque wrench and adhere to manufacturer specifications for all fasteners.

Frequently Asked Questions (FAQ)

- Q1: Can a loose steering stabilizer cause death wobble?

- A loose or faulty steering stabilizer won’t cause death wobble, but it can definitely make the symptoms much worse by failing to dampen oscillations. It’s a symptom suppressor, not a root cause solver.

- Q2: How much does it cost to fix death wobble?

- The cost can vary significantly. Replacing a single tie rod end might be relatively inexpensive, while a complete steering system overhaul or ball joint replacement can run into hundreds or even thousands of dollars depending on parts and labor. DIY saves on labor.

- Q3: Is death wobble dangerous?

- Yes, death wobble is extremely dangerous. It can cause a loss of steering control, leading to serious accidents. It should be addressed immediately.

- Q4: Can larger tires cause death wobble?

- Larger, heavier tires put more stress on the steering and suspension components. If those components are already worn or borderline, larger tires can absolutely trigger or exacerbate death wobble. This is why Jeep suspension issues are so common with modifications.

- Q5: Do all Jeeps get death wobble?

- No, not all Jeeps experience death wobble, but Jeeps, particularly those with solid front axles and modifications like lift kits, are more prone to it due to the stresses placed on the steering and suspension components.

By following this comprehensive guide, you can confidently diagnose and conquer the dreaded death wobble, ensuring your Jeep remains a reliable and enjoyable vehicle. Remember, a well-maintained steering and suspension system is the key to a safe and smooth ride.